jk keeper

JK KEEPER FITTING INSTRUCTIONS

In environments prone to explosions due to the nature of industry e.g. mining, electrical power & control boxes are often used to control & supply power to drilling rigs, ventilation fans, sump pumps etc. Occasionally these boxes are exposed to percussion blast pressures greater than expected which in turn can dislodge a control fuse leaving the box without any power.

The JK Keeper has been designed to hold the Fuse wedge’s during a blast preventing them from being dislodged from their base’s. At present if a fuse is dislodged. This results in the machines not being able to access power from the power supply and recommence work after the blast until a tradesperson can come to fix the problem. This can easily take between half to one hour depending on the location of the box, resulting in unnecessary down time.

Some mines have resorted to fitting Circuit breakers that have a much lower KA rating than the original fuse and cost substantially more than the JK Keeper.

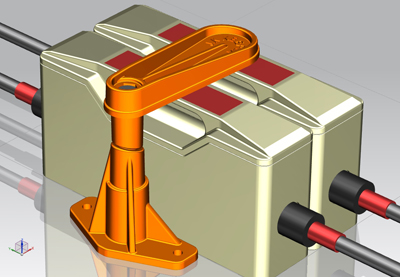

At a reasonable cost the JK Keeper has rectified this problem and is one very easily fitted device. The keeper has been designed to be mounted at either the side or the end of the Fuses depending on the boxes configuration that part number is JKK101.

*100% success rate if installed and maintained correctly as proven in current working mines since 2010.

Estimated JK Keeper cost savings at your mine ...

| Amount of Fuses dislodged/year | 10 Per Year |

50 Per Year |

100 Per Year |

| Cost of Man hours to replace | $1,000 |

$5,000 |

$10,000 |

| Cost of Lost opportunity. (Operating downtime etc.) | $2,000 |

$10,000 |

$20,000 |

| Total loss every year | $3,000 |

$15,000 |

$30,000 |

| Approx. cost of JK Keepers (once off purchase) | $500 |

$2,500 |

$5,000 |

| Total yearly savings (Saving less cost of Keepers first year) | $3,000 |

$15,000 |

$30,000 |

| Total savings 10 years | $30,000 |

$150,000 |

$300,000 |